Mineral Stains is a Leading Innovator in Brick and Masonry Stain Manufacturing

Quality, Service, Affordably Priced

Masonry Stain for Sale – Premium Quality and Fast Shipping!

We exclusively use our proven brick staining products on every project, ensuring long-lasting, professional results. Our Masonry Stains are designed to enhance curb appeal while maintaining the durability and breathability of your masonry surfaces. Looking to buy brick stain? All our products are rigorously tested for performance and shipped within 24–48 hours of your purchase date. We offer both retail and wholesale brick stain solutions, catering to homeowners, contractors, architects and commercial projects across all 50 states. Choose the trusted source for brick stain and masonry restoration products. To Place your order, please visit our Shop page.

A Leader in Specialty Stains

SUITABLE SURFACES

Brick-Stone – Precast – Mortar Joints – Stucco – EIFS – Hardie Boards

CONTACT:

info@mineralstains.com

904-896-7200

About Us

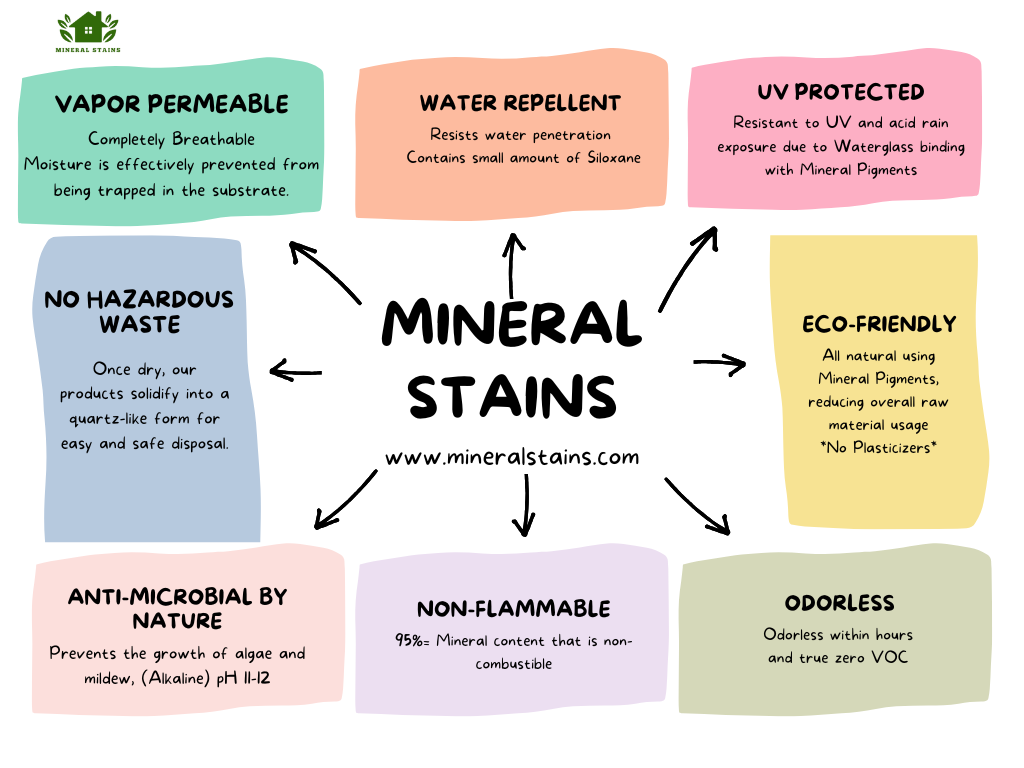

Mineral Stains is a family-owned business specializing in Specialty Coatings, offering personalized products to promote masonry preservation, such as Brick Stain. Our Masonry stains are breathable and eco-friendly, discouraging using latex/acrylic and elastomeric paint on masonry. Our mission is to educate on Masonry preservation, by applying Breathable and UV protected Brick Stain and Masonry Stain on all masonry absorbent surfaces. We provide color options from NCS and RAL fan decks, with color-matching services for Sherwin Williams and Benjamin Moore paints available upon request, for an additional fee. Check out how we got started!

Why Stain?

- Proper Breathability·

- Preserves Structural Integrity·

- UV Protection (color will not fade)·

- Fire Repellent

- Longevity/Maintenance Free·

- Curb Appeal (adds value)

- Affordable

- Avoids Flaking/Peeling

Our Mission Statement

To apply breathable Mineral Stain coatings that preserve and protect masonry without causing harm, aiming to preserve as many masonry buildings as possible.

- Our brick and masonry stains can last up to 20 years or more under proper conditions.

- Our Brick Stain is UV-protected and breathable, with a high pH of 11-12 to deter mildew and algae.

- Unlike synthetic paints, our stains do not deteriorate or break down masonry.

- Our brick and masonry stains are eco-friendly and use earth pigments instead of synthetic ones.

- Our masonry stains contribute to a more sustainable environment, aligning with our commitment to discourage the use of latex/acrylic and elastomeric paints on masonry surfaces.

- We offer a wide range of color options using NCS and RAL fan decks.

- We also provide color matching services for Sherwin-Williams and Benjamin Moore paints upon request.

- Suitable Surfaces: Brick – Stone – Precast – Mortar Joints – Stucco – EIFS – Cement Fiber (Hardie Boards)

Revamp Your Home's Look with Exterior Brick Stain: A Complete Guide to Staining Exterior Brick

Exterior brick staining is a fantastic way to refresh and personalize your home’s appearance without costly renovations. Unlike paint, which sits on the brick’s surface and can peel over time, stain penetrates deeply into the brick pores, preserving its natural texture while providing a long-lasting, vibrant finish. Staining also offers greater flexibility in color choices, allowing you to achieve anything from a natural, earthy tone to a more modern, bold color.

In this guide, we cover everything you need to know about staining exterior brick. From the benefits of staining over painting to selecting the right stain and preparing the surface, we offer step-by-step instructions to help you achieve a professional look. Whether you’re looking to increase curb appeal for resale or simply want a fresh aesthetic, exterior brick staining is a durable and customizable solution that brings new life to your property. Discover how this process works, tips on choosing the perfect stain, and best practices for application. With proper care and the right products, you can enjoy a beautifully stained brick exterior that stands up to the elements and maintains its charm for years to come.

Our Products

Staining Through Time: A Brief History

Brick staining, a practice spanning centuries, has evolved significantly. In 18th century England, bricks were coated with cow dung mixed with milk or yogurt to encourage aging, later using a water and soot mixture. However, imprecise color and durability were issues. In the late 1800s, King Ludwig’s quest for a durable winter paint led to the discovery of silicates. This stain transformed building colors, enduring harsh winters. Innovations have extended the stain’s lifespan to over 20 years, with some European buildings maintaining color for a century without maintenance.

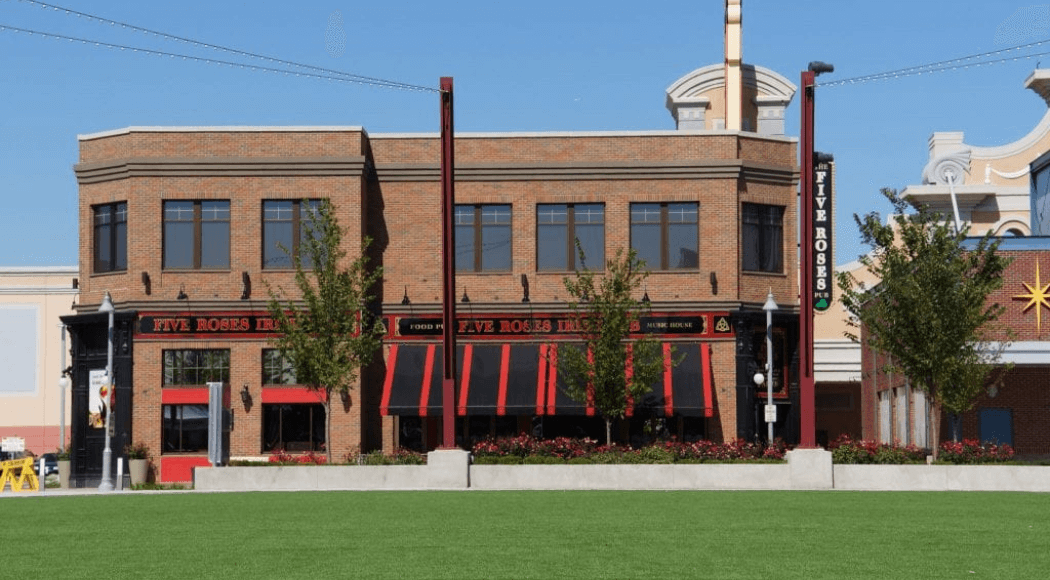

Experience the transformative power of Mineral Stains in action! The Saltwater Project in Rosemont, IL, stands as a testament to the skill of our installers. Be captivated by the remarkable change brought about by our Masonry Stain in a timeless Alabaster finish. Beyond the aesthetic appeal, our products offer additional benefits, Breathability, UV protection, and low maintenance. Witness the fusion of innovation and artistry as Mineral Stains enhances the beauty and longevity of masonry surfaces. The Saltwater building underwent a meticulous Brick Stain application, providing the bricks with an extended life while avoiding any compromise due to moisture entrapment.

What Our Clients Say

EXCELLENTTrustindex verifies that the original source of the review is Google. Fantastic products and customer service. Matt was extremely knowledgeable on his products, spending lots of time with me answering questions and providing guidance on my project. The stain penetrated and covered the brick very well. The painters were impressed with the stain and its application (Antique Beige). We couldn't be happier with the stain and the finished product. Highly recommended.Trustindex verifies that the original source of the review is Google. I highly recommend Mineral Stains as a quality alternative to paint. The product is superior and spruces up the exterior of a house or building while also providing a longer lasting professional look.Trustindex verifies that the original source of the review is Google. Outstanding products with excellent support. Highly recommendedTrustindex verifies that the original source of the review is Google. Matt from Mineral Stains was very quick and responsive with our order. After doing some research, the consensus is that you never want to paint brick but staining brick is a much better option. The product is phenomenal and super easy to apply. We took our dated red brick and transformed it to a modern looking dark/black brick. I couldn't be happier with the results. This was the product I was looking for! Mineral Stains made every aspect of the transaction fast, easy, and convenient.Trustindex verifies that the original source of the review is Google. I would definitely recommend to anyone who is looking to enhance or want a new look to their old brick . Matt is very knowledgeable and his product is solid good quality. I did a sample of the side brick with two different colors to decide which color is a best fit that was 6 months ago it look like I did it yesterday. I finally found time to stain it been busy but it came out better than expected. Also the stain makes it a natural look vs paint.Trustindex verifies that the original source of the review is Google. Great product and great company. The owner Matt is terrific. Spent so much time with me on the phone explaining the product and its application. Really appreciated it. Converted a pretty ugly red brick wall to his Slate color and it looks awesome. Highly recommend.Trustindex verifies that the original source of the review is Google. Matt was SUPER responsive and extremely helpful. I had so many questions, and he (patiently) addressed each one in a timely manner. The product worked as described, and was easy to apply myself. It completely transformed the look of my very outdated breezeway. The stain looks as if it had always been part of the brick. I love the space now! Sorry that my pics aren't from the same angle 🙂Trustindex verifies that the original source of the review is Google. Matt was great to work with. Very knowledgeable of the types of products to use for the application I had. Not just another salesman just trying to sell you something and move on to the next one.Trustindex verifies that the original source of the review is Google. Matt (the owner) provided exceptional service when we purchased brick stain to change the color of our building. He was incredibly knowledgeable and patient, spending a lot of time ensuring we were applying the stain correctly. Thanks to his guidance, the result looks fantastic! Highly recommend Matt for anyone looking to enhance their building’s appearance with quality brick stain and expert advice.Trustindex verifies that the original source of the review is Google. Great quality, great customer service. Dealt with Matt and he guided me thru the whole process. I will for sure recommend to anybody!

Masonry Preservation

“Our mission is to breathe new life into each building, preserving its legacy one structure at a time. We are dedicated to revitalizing without compromising the integrity of its masonry, ensuring a lasting and beautiful transformation.”

Step 1: Check Absorbency for Brick Stain

The initial step in the brick staining process involves assessing the brick’s absorbency. We meticulously examine the surface to determine how porous it is, helping us tailor the staining approach for optimal results.

Step 2: Check for Moisture Before Brick Staining

Moisture content is crucial for a successful staining application. Our experts conduct thorough moisture checks to ensure the bricks are adequately dry, preventing any issues with adhesion or discoloration.

Step 3: Apply the correct Primer for Brick Stain

Applying the right primer is a critical preparatory step. Our team selects and applies a primer suitable for your specific brick type, enhancing the bonding capacity of the stain and ensuring a lasting, vibrant finish

Step 4: Apply Our Premium Brick Stain

Our meticulous application of premium brick stain, chosen for quality and eco-friendliness, seamlessly integrates with the brick surface, ensuring durability, UV protection and breathability.

The Difference between Brick Staining vs Painting

Materials Used:

- Staining: Made with inorganic pigments, solvents, and binders. Penetrates the surface, enhancing natural grain and color.

- Painting: Made with organic pigments, binders, solvents. Forms a surface film, covering the original appearance.

Texture:

- Staining: Retains natural texture as it penetrates pores, avoiding a plastic like surface film.

-

Painting: Creates a smooth, uniform surface, masking natural texture, entrapping moisture, also destroying masonry.

Application Process:

- Staining: Applied with a brush, roller, or sprayer, absorbed into the surface.

- Painting: Applied with similar tools, forming a protective film over the surface.

Maintenance:

- Staining: In most cases, will not require reapplication of stain or protective finish.

-

Painting: Requires frequent maintenance, also may need touch-ups over time, due to UV and Breathability

Long-term Considerations:

- Staining vs. painting brick is more cost-effective over time, considering additional coats and maintenance.

- Staining ensures proper breathability, preventing brick or masonry destruction, offering a matte finish versus the cheaper and shinier appearance of paint. Stain will also be UV Protected

Appearance:

- Staining: Applies a solid or transparent finish, enhancing natural texture and color hue.

- Painting: Applies opaque paint, forming a solid coating that covers natural texture and color variations.

Color Options:

- Staining: Offers various colors, semi-transparent or translucent, allowing natural variations to show through.

- Painting: Provides a wide range of colors, including custom options, offering complete coverage over original color.

Durability and Protection:

- Staining: Penetrates, providing protection against moisture, UV rays, and elements, lasting up to 20 years.

- Painting: Forms a barrier, protecting against various damages, may require occasional touch-ups.

Suitability (Surfaces):

- Staining: Suitable for masonry surfaces: brick, stone, cement fiber boards, precast, and drywall.

-

Painting: Applicable to a wide range of surfaces including wood, metal, plaster, and drywall.

Summary:

- Staining and painting offer different aesthetic effects and durability characteristics.

-

Choice depends on factors like appearance preference, color options, and maintenance.